Tapes for welding processes

Conveyor belts for industrial welding processes

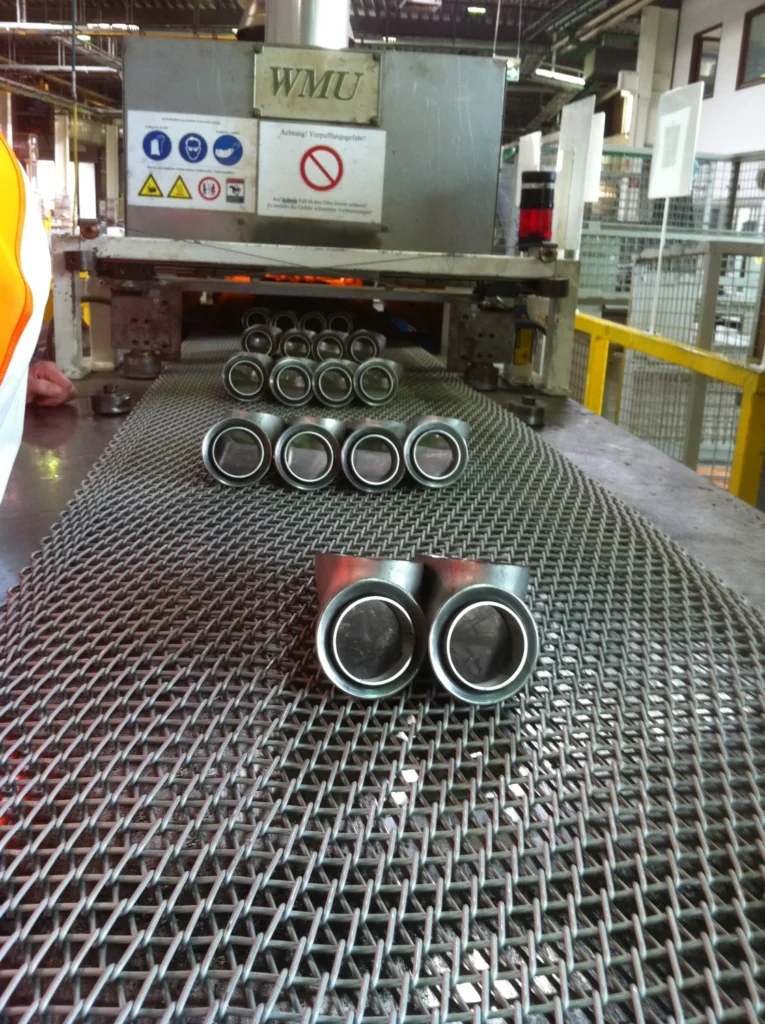

Brazing is a process of continuous and semi-automatic production, by which two metallic components are joined with a filler metal lower than the composition of the components to be joined, at a given temperature. This type of production process allows designers and production engineers to join simple or complex designs that have a joint or several. Some of its applications include: aerospace components, automotive components, electronic devices, among others. The conveyor belts used for this type of process are mainly manufactured with AISI 314 / 25-20 / 1.4841 or AISI 330 / 37-18 / 1.4864

Codina can also manufacture such conveyor belts for welding processes in other materials on demand.

Materials for conveyor belts in the welding industry

AISI 314/25-20/1.4841

This material is suitable for processes whose execution temperature is between 900°C and 1160°C. However, this material is not suitable for processes where the tape can work during some phase between 750ºC and 850ºC, since it becomes fragile by sigma phase formation.

AISI 330/37-18/1.4864

Corrosion and high temperature resistant material, offers high mechanical and carburizing resistance. It can work at temperatures up to 1160°C. The main property of this material is that it remains austenitic during the temperature range of the Sigma phase (750-850°C).

Conveyor models most used in the sector

Conveyor belts for welding in different sectors and uses

Welding material transport belts

- Transport of metal parts to welding stations.

- Movement of components along assembly lines for sequential welding.

Conveyor belts for integration into automated welding cells

- Conveyor belts for automated welding robots.

- Coordination of the movement of pieces with robotic welding arms.

Conveyor belts for in-line welding systems

- Continuous transport of parts through welding stations.

- Optimization of production flow through in-line welding.

Precise parts positioning

- Exact alignment of welding parts.

- Support for fixing parts during the welding process.

Welding of electronic components

- Transportation of printed circuit boards (PCBs) for welding of electronic components.

- Maintenance of stability and precision during the welding of sensitive electronic components.

Welding of large structures

- Transport of large metal assemblies, such as car structures or heavy machinery.

- Movement of structures through welding stations for welding processes in multiple stages.

Pipe and pipe welding applications

- Transport of pipes and pipes for butt welding or circumferential welding.

- Support for rotation of tubes during welding.

Resistance welding processes

- Movement of parts to resistance welding stations (by spots or seams).

- Transport of conductive materials through resistance welding processes.

Laser welding

- Transport of parts to laser welding stations.

- Maintenance of accurate alignment for high-precision laser welding.

Car body welding

- Transport of panels and body components for assembly and welding.

- Coordination with welding robots in automotive production lines.

Aviation component welding

- Movement of aircraft parts for high-precision welding processes.

- Transport of structural components for assembly and welding in the aeronautical industry.

Welding in the metal furniture industry

- Transport of metal furniture pieces for welding and assembly.

- Movement of components through welding stations in the manufacture of furniture.

Welding of pressure vessels and boilers

- Transport of plates and components for assembly and welding of pressure vessels.

- Movement of large structures through welding processes for industrial boilers.

Welding of construction equipment

- Transport of components of construction equipment for assembly and welding.

- Movement of large and heavy parts through welding stations.

Welding in the manufacture of household appliances

- Transport of parts and components for assembly and welding of household appliances.

- Coordination of production flow in the manufacture of metal appliances.