Sliding supports and drive haulage systems

![]()

[br]

[br]

[br][br]

[br][br]

[br][br]

[br][br]

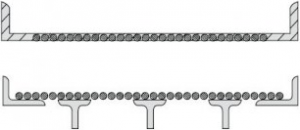

All the simple conveyor belt range, besides the derived types (not standard), may become composed conveyor belts when the accessories hereunder make part of their construction:

- Side wings: to prevent the product from falling over the sides of the belt, and its shape and height can vary (types C.A-L, C.Al-L, etc.).

- Crosswise strips: to hold the product whenever the belt operates on inclined planes. Angle bars fastened to flatbars by screws or directly welded onto the belt mesh are commonly used. In principle, their height has no limitations (types C.A-T, C.Al-T, etc.). The belts can be also manufactured with wings and strips

(types CA-L-T, CA1-L-T, etc). - Side chains: to ease belt haulage and ensure proper drive preventing the wire mesh from being subject to the wear and tear resulting from the dynamic motion of the belt. The most standard pitches are used, such as 9.52 mm, 12.70 mm, 15.87 mm, 19.05 mm, 25.40 mm, 38.10 mm and 50.80 mm (types C.A ... , C.AL., etc.). However, the belts can be manufactured at the size our customers may require, by linking the chain to the belt at each pitch or at N pitches. The chain belts can be also manufactured with side wings and crosswise strips (types C.A1..., e.A1...L, C.A ... L. .. T, C.A1. .. L. .. T, etc.). ( ... ) Fill in the chain pitch on the belt type suspension points.

Besides these usual accessories, composed conveyor belts can be manufactured equipped with continuous or perforated sheet flatbars inside the spirals. U-shaped strips, high spirals, fork-shaped finished rods, etc. Our Technical Department can study and execute any handling our customers may require, no matter how complex it may be.

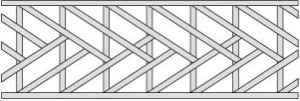

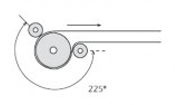

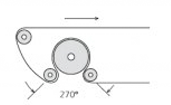

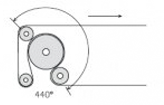

Drive haulage systems

Thrust haulage (high temperatures)

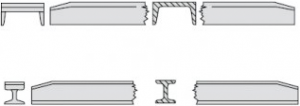

Belt installation

-

- Disconnect the old belt at the lower side of the driving cylinder and attach a cable at one end. When the belt is pulled out the cable must be fitted to the conveyor, allowing the new belt to be charged.

-

- To check all the conveyor guides and cylinders (driving, return, tensioning, supports, etc) all these cylinders must be at 90° in respect of the middle line of the conveyor and perfectly parallel between themselves.

-

- To check the supports or sliding guides of the belt. Ensure there are no sharp edges or elements that could rub and waste the belt.

- On completion of checking and cleaning the conveyor, we will proceed to introduce the new belt by using the cable that we have previously placed in the conveyor when removing the old belt.

If no maintenance is required, we may just change the belt by joining the new belt to the old one when removing it.

Almost every belt has a running direction, so this must be taken into consideration when placing the new belt into the conveyor.

Product load and belt starting

Product load

The product load on the belt must be as uniform as possible to evenly distribute the weight on the lower side, thus preventing distortion and premature belt failure.

Belt starting

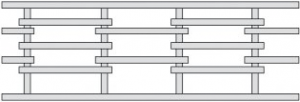

For conveyors that operate at an ambient temperature, we will pre-tense the belt and gradually the speed until reaching the working speed. We must observe that the belt remains straight, with no friction on the sides.

We should never line up or place the belt by scraping along the edges. The lining up must be done by correcting the cylinders (driving, return, supports, etc.).

A high temperature belt must run in a similar way to any other precision part . The oven must increase its temperature at a speed not higher than 148ºC per hour. Once the working temperature has been reached, the belt must work about 5 hours without any load to ensure the correctly settling-down of the belt elements (spirals and cross bars). Changes in temperature affect the breaking properties of the metal and close attention is needed to determine any belt adjustment that may be required during this period.

During the rolling period we must eliminate any tension in the belt to ensure its maximum working life. In addition we avoid any excess in the growth of the grain by annealing it an adequate temperature.

The process of avoiding the tensions may be further achieved with the following two suggestions:

- For alloys that work at 925ºC or over the treatment of tension elimination must be quite long, so that each section of the belt should work at a minimum 925ºC for an hour.

- For alloys that work at 898°C or under the treatment of tension elimination must be done at 28ºC

above the normal temperature for sufficient time for each section of the belt to reach the temperature of tension elimination for at least one hour.

Once the tension elimination treatment is completed, we continue to increase the oven temperature at arate of 164ºC per hour, until the final working temperature is reached. At that point, the belt must run a minimum of 5 hours without any load.

Generally, the high temperature belts have a centain amount of tension predeterminated before an failure in the tension occurs. The intentional tension of the belt only saves so me hours of maintenance at the expense of the belt long term durability.

Stopped belt

When the belt is stopped the following precautions are essential, in order to obtain the maximum service life:

A .- The belt must be stopped with the operational temperature working.

B .- The belt tension must be reduced to the minimum needed to engage the drive sprockets properly or adjusted according to the manufacture's documentation. This applies in particular for high temperature ovens, which are equipped with a counterbalance or air cylinders fot the belt take-up at the extreme unloading end. The high counter tension conveys along the belt in such a way that the tension in the heated area may be bigger than where the belt carries the load.

C .- A high temperature belt must be maintained in motion, if stopped it may weld to the support of the oven and cause serious damage when restarted.

D .- Regular tests regarding the direction of the belt must be carried out without load, as the changes of temperature induce quite often to changes in the run.

In this chapter, "BELT STOP" stop is understood without any load on the belt.