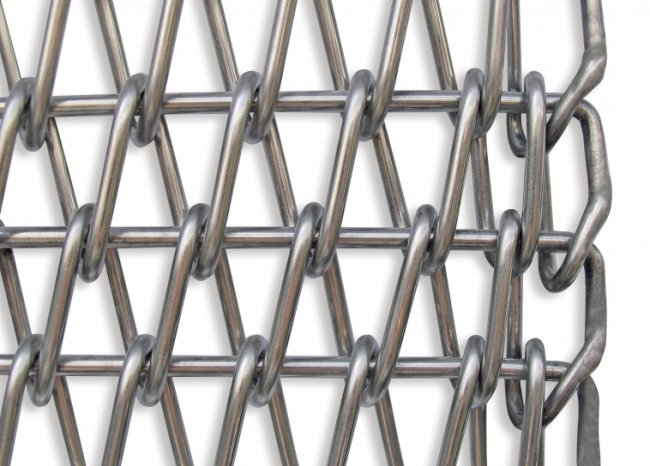

Conveyor belts for Brazing processes

Brazing is a continuous and semiautomatic production process wherein two metal components are joined, at a predefined temperature, by means of a filler metal whose composition is inferior to that of the other two metals being joined. This type of production process allows designers and production engineers to create simple or complex designs containing one or more joins. Some of its applications include: aerospace components, automotive components, electronic devices, and more. The conveyor belts used for this type of process are primarily manufactured with:

AISI 314 / 25-20 / 1.4841 This material is adequate for processes whose temperature of execution is between 900°C and 1160°C. Regardless, this material is inadequate for processes in which the belt may have to operate during a phase between 750°C and 850°C, since the material becomes fragile as a result of sigma phase formation.

AISI 330 / 37-18 / 1.4864 Material resistant to corrosion and high temperatures; offers a high degree of mechanical resistance and resistance to carburization. Capable of operating at temperatures of up to 1160°C. The main property of this material is that it remains austenitic during the sigma phase temperature range (750-850°C).

CODINA can also manufacture this type of welding conveyor belt with other materials, upon request.