heat treatment

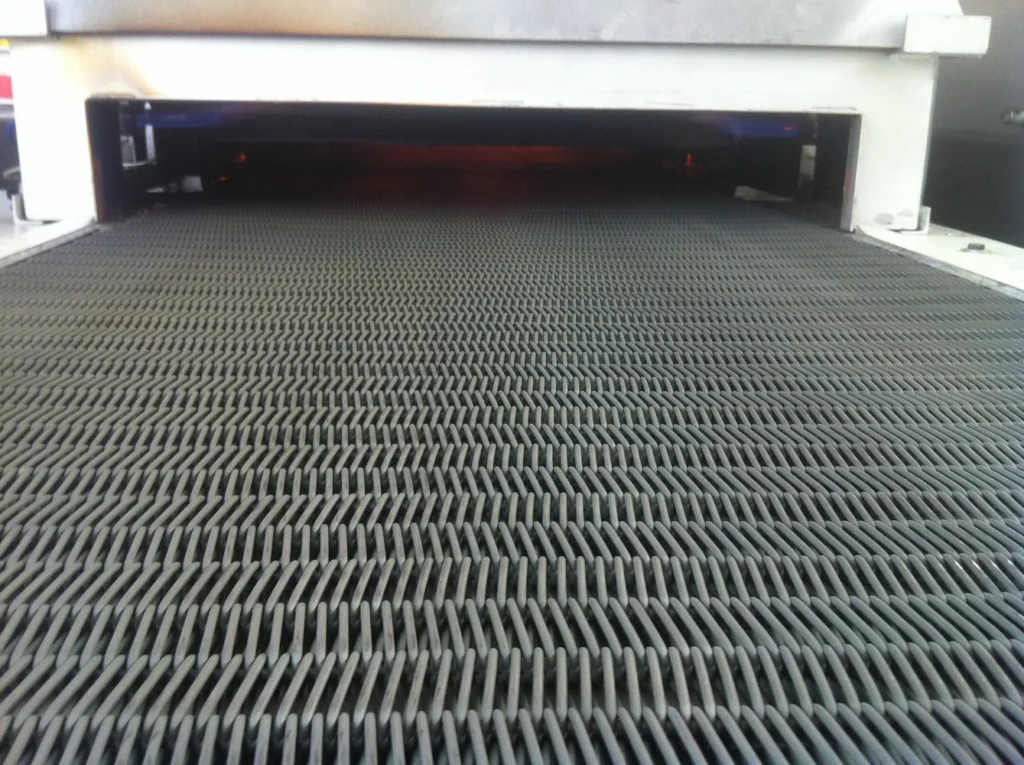

Metal Conveyor Belts for Heat Treatment Processes

The heat treatment of steel and foundries is a process consisting of a set of heating and cooling operations, under controlled conditions of temperature, speed, time and pressure, of metals or alloys in the solid state, in order to improve their mechanical properties.

This type of production process allows to considerably improve the hardness, strength and elasticity of treated metal materials.

The steel heat treatment belts and foundries that we manufacture in Codina can work at temperatures up to 1160ºC and Sigma phase temperatures since we use top quality materials to create our conveyor belts specifically created for high temperature processes.

Materials used in our conveyors for heat treatment

AISI 314/25-20/1.4841

This material is suitable for processes whose execution temperature is between 900°C and 1160°C. However, this material is not suitable for processes where the tape can work during some phase between 750ºC and 850ºC, since it becomes fragile by sigma phase formation.

AISI 330/37-18/1.4864

Corrosion and high temperature resistant material, offering high mechanical and carburizing resistance. It can work at temperatures up to 1160ºC. The main property of this material is that it remains austenitic during the temperature range of the sigma phase (750-850ºC) and supports for a long time the formation of this phase.

Codina can also manufacture this type of tape on other materials on demand.

Conveyor models most used in the sector

Conveyor belts for heat treatment in different sectors and uses

metallurgical industry

- temper and temper: Transport of metal parts through ovens for the process of hardening and relieved stresses.

- Cementation and carbonitration: Mobilization of metal components during the process of adding carbon or nitrogen to the surface to improve its hardness.

- Annealing: Transport of metals to homogenize the structure and eliminate internal stresses.

Automotive industry

- Heat treatment of engine parts: Transport of engine components, such as crankshafts and connecting rods, through ovens to improve their mechanical properties.

- Manufacturing of transmission parts: Mobilization of gears and axles for heat treatments that improve their strength and durability.

- induction hardening: Transport of specific parts through rapid heating and controlled cooling processes.

Tools and machinery industry

- Manufacturing of cutting tools: Transport of high-speed steels and carbide through furnaces for heat treatment that improves hardness and wear resistance.

- Production of molds and dies: Mobilization of metal molds and dies for heat treatments that improve their durability and precision.

electronics industry

- Treatment of semiconductor components: Transport of silicon wafers and other semiconductor materials through high-temperature furnaces for doping and tempering processes.

- Integrated circuit production: Mobilization of circuits and electronic components during heat treatment processes to improve their performance and reliability.

glass industry

- Glass annealing: Transport of glass through annealing furnaces to eliminate internal stresses and improve resistance.

- Heat treatment of laminated and tempered glass: Mobilization of glass panels through thermal processes to improve their safety and durability.

pottery industry

- Ceramic sintering: Transport of ceramic components through sintering furnaces to improve their density and mechanical resistance.

- tile and tile treatment: Mobilization of tiles and tiles through ovens for heat treatment that improves its hardness and surface finish.

energy industry

- Turbine component treatment: Transport of metallic turbine components through heat treatment processes to improve its resistance to high temperatures and wear.

- Production of power generation equipment: Mobilization of critical parts through heat treatments that improve their mechanical properties and corrosion resistance.

aerospace industry

- Treatment of light alloys: Transport of aluminum and titanium parts through heat treatment processes to improve its mechanical properties and resistance to fatigue.

- Solution and aging furnaces: Mobilization of aerospace components through solution furnaces and aging to optimize strength and durability.

defense industry

- Treatment of military equipment: Transport of metallic components of military equipment through heat treatment processes to improve its strength and durability.

- Armament production: Mobilization of pieces of weapons through ovens for heat treatments that improve their performance and reliability.

Conveyor belts for heat treatment of advanced materials

- Treatment of composite materials: Transport of advanced materials through heat treatment processes to optimize their mechanical and thermal properties.

- Production of superalloys: Mobilization of superalloys through furnaces for heat treatments that improve their strength and performance in extreme conditions.