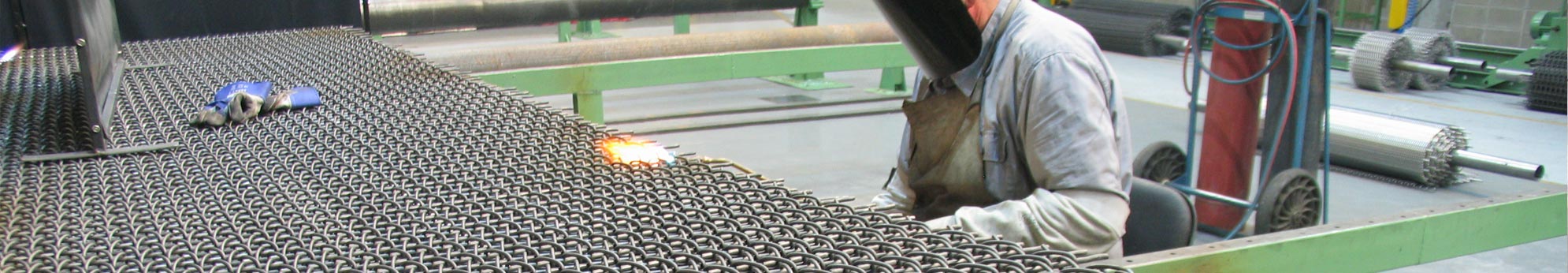

Conveyor Belts for blasting processes

The blasting process is specific for the surface treatment of high performance aluminum and steel components. The process is carried out after the production of the pieces, placing the material on top of the conveyor belt and transferring the pieces to the blasting chamber. Then, a series of turbines, positioned above and below the conveyor belt, determines the treatment of all exposed surfaces.

Continuous blasting is used to ensure high productivity, with a variety of dimensions and shapes to be treated. So, this process is designed for high production of parts: stamping, casting, aluminum automotive parts, sintering, etc.

This is the subtitle

Uses of Conveyor Belts in Shot Blasting Processes by Industry

Automotive Industry

- Aluminum and Steel Component Transport:

- Move aluminum and steel engine, chassis, and body parts through the shot peening chamber.

- Ensure uniform treatment of all exposed surfaces through controlled movement on the conveyor belt.

- Stamping and Casting Production Lines:

- Continuous transport of stamped and cast parts for shot peening.

- Increase the efficiency of the automated production line.

Aerospace Industry

- Structural Component Transport:

- Moving structural parts and aircraft components through the shot peening chamber.

- Providing uniform and efficient treatment to ensure clean, prepared surfaces.

Metalworking Industry

- Cast Parts and Metal Surfaces:

- Transporting castings through the shot peening process to remove mold residue.

- Moving metal surfaces to prepare for coating and weld adhesion.

Construction Industry

- Steel Structural Components:

- Transport beams, columns, and structural components to the shot blast chamber.

- Ensure removal of rust and preparation for painting or coating.

- Equipment and Machinery:

- Move construction equipment and machinery through shot blasting for maintenance and repair.

Energy Industry

- Generators and Turbines:

- Transport generator and turbine components to the shot blast chamber.

- Ensure surface treatment for coating application

- Pipes and Pressure Vessels:

- Moving pipes and pressure vessels through shot peening to remove oxides and contaminants.

Appliance Industry

- Metal Components:

- Transporting metal appliance components through the shot peening chamber.

- Ensuring a clean, uniform finish for subsequent coating application.

Railway Industry

- Carriages and Locomotives:

- Moving components of cars and locomotives through the shot blasting process.

- Treating axles and wheels to remove rust and contaminants.

Conveyor belts for shot blasting in the Naval Industry

- Hull Surfaces:

- Transporting hull surfaces to the shot blasting chamber to remove rust.

- Preparing the surface for the application of anti-corrosion paints and coatings.

- Marine Machinery Components:

- Moving metal components through the shot peening process to ensure a clean finish.

Metal Furniture Industry

- Metal Furniture:

- Transporting metal furniture components through shot peening.

- Preparing surfaces for paint and other coatings.

Shot Blasting Conveyors in the Medical Equipment Industry

- Surgical Instruments:

- Moving aluminum and steel surgical instrument parts through the shot blast chamber.

- Ensuring clean, contaminant-free surfaces.

- Medical Equipment Components:

- Transporting metal components through the shot blast chamber to improve finish.

Tools and Machinery Industry

- Cutting Tools:

- Moving cutting tools through the shot blast chamber to remove waste.

- Improve surface finish.

- Machinery Components:

- Transportation of machinery parts through shot blasting for maintenance and repair.

Ask without obligation

We will help you find the conveyor belt you need

Other uses of Codina conveyor belts

Sintering

Continuous production process in which the metallic or ceramic powder temperature ...

Heat treatment

Heat treatment of steels and cast iron production is a process consisting of a set of heating and cooling ...

Food

Freezing tunnels, cooling and freezing towers, ovens for the baking of bread or biscuits ...

Brazing processes

Brazing is a metal-joining process whereby a filler metal is heated above melting point and distributed between...