Features

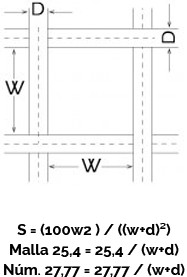

D: Wire diameter in mm.

W: Mesh opening. Distance in mm. between two adjacent wires.

Besides the material of the wire used and type of cloth, some other features stated on the table:

S%: Working surface. Approximate percentage of the total surface of the openings of a mesh.

Kg/m2: Approximate weight in kg of a m2 of an iron/steel woven wire cloth. (See conversion factor table for other materials).

Núm: Mesh number. It is the quantity of mesh openings in a given length unit. The woven wire cloth is formally defined by parameters W and D, so this information is merely a guidance to give a simple description of the mesh. But it is included herein since it is still widely used in two different versions, calculated as follows (in mm.):

S = (100w2 ) / ((w+d)²)

Mesh 25,4 = 25,4 / (w+d)

Num. 27,77 = 27,77 / (w+d)

Meshes

Densities and conversion factors

To obtain the approx. weight in Kg/m2 of the mentioned materials, multiply the weight of the general chard by the coefficient Fc. To bear in mind that the indicated weight in the chart is for stainless steel.

The ISO 9044 standards (issued by International Organization for Standardization) will rule any matter related to technical requeriments, tolerances and conditions of the woven wire cloth for industrial use, such as defined therein.

| Material | g/cm3 | FC |

|---|---|---|

| Iron/Steel | 7850 | 1000 |

| Stainless steels | 7930 | 1000 |

| Aluminium | 2700 | 0.343 |

| Cooper | 8900 | 1134 |

| (Cu Zn37) Brass | 8450 | 1076 |

| (Cu Zn20) Brass | 8650 | 1102 |

| (Cu Sn6) Phosphor bronze | 8800 | 1121 |

| Monel Alloy 400 | 8810 | 1122 |

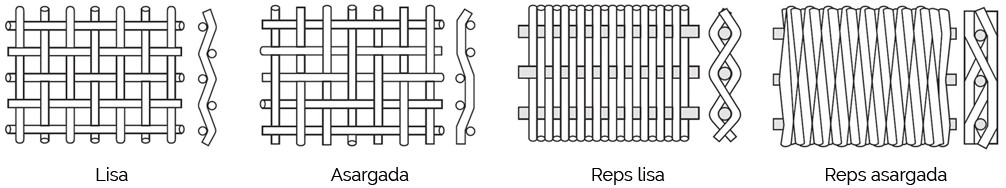

Reps

| Malla 25.4 | Filtracion en | D (mm) | Kg/m2 |

|---|---|---|---|

| 12x64 L/P | 350 | 0.58-0.43 | 4.01 |

| 12x64 L/P | 280-300 | 0.61-0.41 | 3.90 |

| 24x110 L/P | 112-125 | 0.36-0.26 | 2.70 |

| 30x150 L/P | 98-105 | 0.23-0.18 | 1.60 |

| 40x200 L/P | 75-80 | 0.18-0.14 | 1.35 |

| 50x250 L/P | 60-65 | 0.14-0.12 | 1.20 |

| 60x570 A/T | 50-55 | 0.17-0.10 | 1.85 |

| 80x700 A/T | 35-40 | 0.10-0.08 | 1.32 |

L/P : Tejido liso A/T : Tejido asargado