What are metal fabrics? And what are they for?

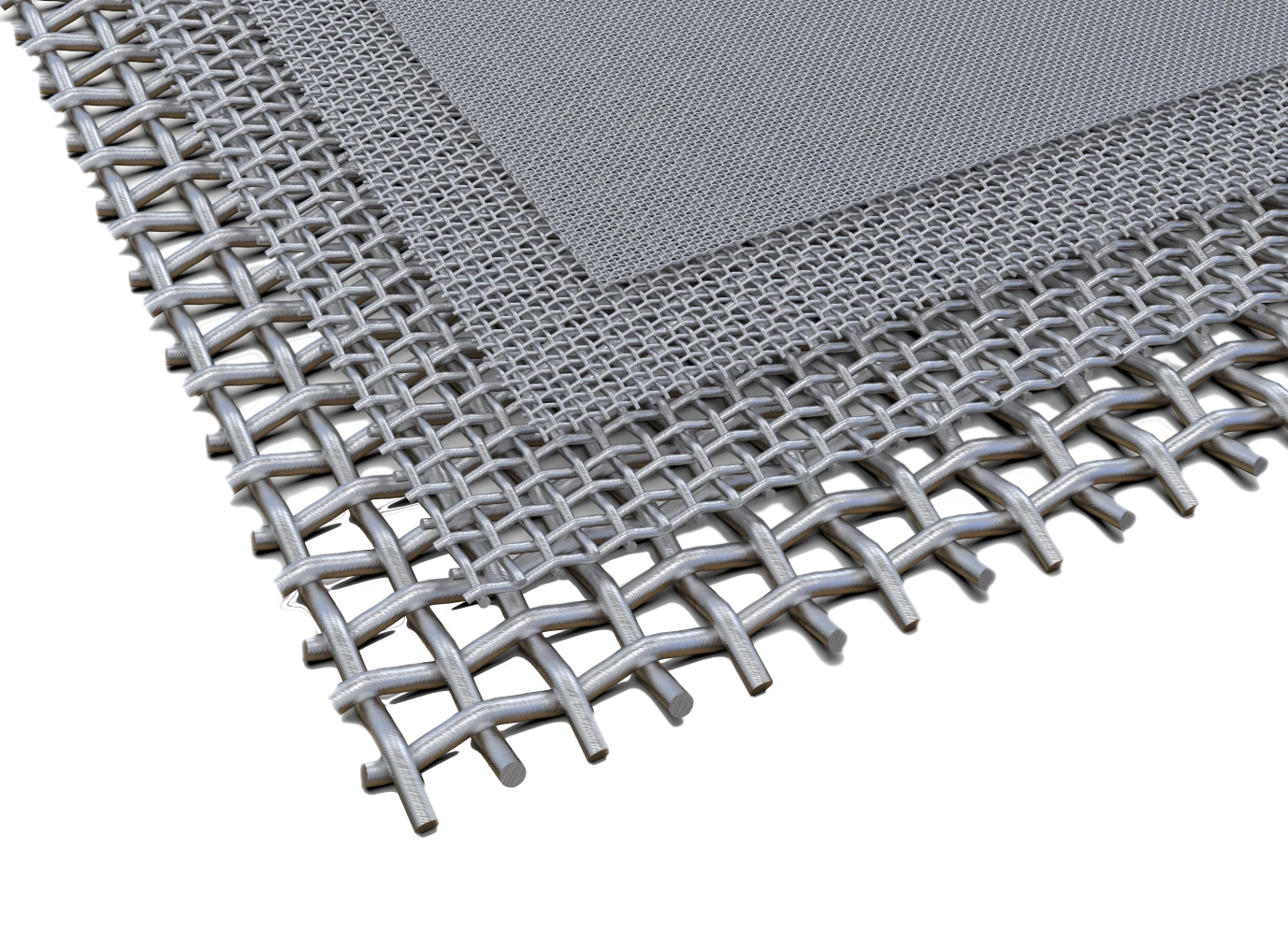

Las metal fabrics They are flexible and woven sheets formed by threads or wires of metal interlaced in a manner similar to a textile fabric. They are characterized by being very resistant and versatile, which makes them fundamental elements in various industries.

these meshes They can be manufactured in different configurations, depending on the type of fabric and the materials used, adapting to various technical and environmental requirements.

Las Metal fabrics have multiple functions in the industrial and architectural field.

They are mainly used for Filter, sift, protect and transport materials in production processes.

They also play an important role in the decoration Architectural and the Interior design.

Advantages of metal fabrics

Durability

Resistant to corrosion, high temperatures and abrasion.

Versatility

Different materials and types of fabric for every need.

mechanical resistance

Support high loads without deformation

Easy maintenance

They are simple to clean, which is essential in applications such as food processing or chemicals.

- materials and manufacturing

Manufacture of metal fabrics

The manufacture of metal fabrics is carried out through a process of tissue of metal wires. These wires can be intertwined in various configurations, such as smooth, elongated or Dutch (REPS) fabric, depending on the application needs.

materials used

| Material | Features |

|---|---|

| Iron | Good mechanical resistance. |

| Steel | High structural strength. |

| Stainless steel | Anti-corrosion and long service life. |

| Aluminum | Lightweight and resistant to rust. |

| Copper | High thermal and electrical conductivity. |

| Brass (Cu Zn37, Cu Zn20) | Strong and malleable. |

| Phosphor bronze (Cu Sn6) | Durable and corrosion resistant. |

| Monel 400 alloy | Excellent chemical and mechanical resistance. |

Types of metal fabrics