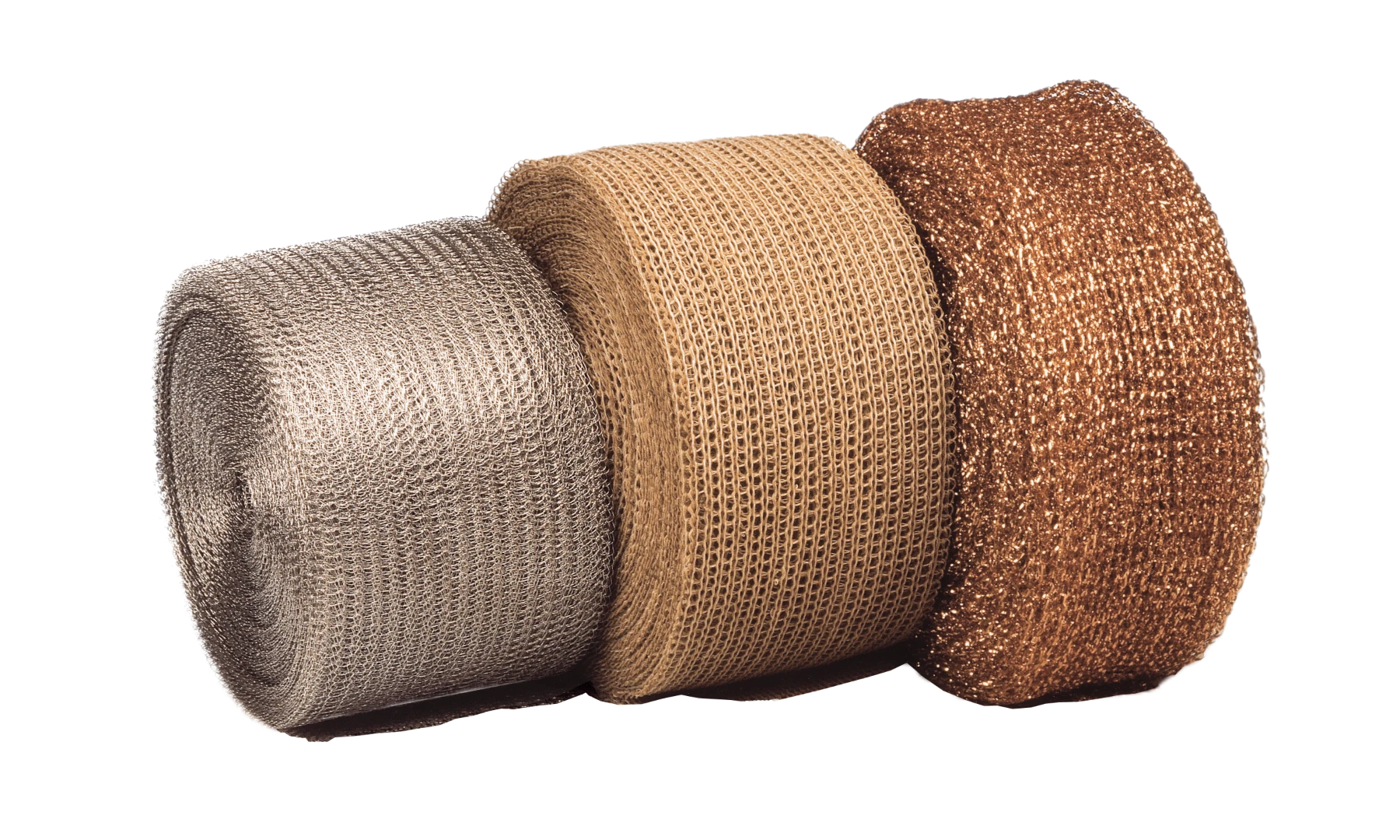

Knitted mesh manufacturing: precision, variety of geometries and industrial materials

Las knitted meshes are marketed In the form of a continuous flattened sleeve whose structure is based on a series of beautiful and decorative link arches that are interwoven by the folds of the thread.

These meshes, due to their great ductility, They allow to build bodies of a very varied geometry and density that give them relevant physical and technical qualities that make them suitable to satisfy a wide range of industrial applications.

Our great experience in drawing technology, such as One of the first industries in the manufacture of metal fabrics, places us in unbeatable conditions to overcome the most demanding technical conditions in quality and variety of materials.

Likewise, our great production capacity allows us to Store important raw material reserves To be able to serve any order at very competitive prices.

Our manipulative factory, equipped with a highly qualified staff and the right technology, Produces diverse application components under specific specifications, both in fabrics and in knitted mesh.

We are prepared for Serve from unit manufactures to large series, even units whose weight is a few grams to dimensions typical of the petrochemical industry.

Table of measurements, light and weight of knitted mesh

The table shows a wide range of tights Knitted whose characteristics conform to the most frequently used applications, including dimensions, mesh light and linear weight, facilitating the appropriate selection for each industrial need.

| To | b | C | D | And | f |

|---|---|---|---|---|---|

| 60 | 60 | 55 | 36 | 2×4 | 54.24 |

| 120 | 150 | 100 | 34 | 4.5×4 / 2.5×4 | 64.54 |

| 140 | 150 | 120 | 40 | 4.5×5.5 / 2.5×5.5 | 65 |

| 200 | 205 | 180 | 56 | 4×3.5 / 2.5×3.5 | 105.4 |

| 250 | 260 | 240 | 65 | 4×4/ 3×4 | 123.22 |

| 410 | 420 | 380 | 94 | 5.2×3.5 / 3×3.5 | 198 |

| 560 | 565 | 490 | 102 | 7.5×5 / 2×5 | 195.16 |

| 560 | 560 | 470 | 128 | 5×4 / 2.5×4 | 270 |

- A: Normal mesh width that comes out of the machine once flattened (tube flattened).

- B: Maximum width that can get out of the machine.

- C: Minimum width that can get out of the machine.

- D: number of needles of the machine.

- E: Mesh light. also counted in the nominal width. In the machines that we give 2 mesh lights are:

First: It is the light that remains between two needles.

Second: It is the hole of the needle itself, that is, there is a light from each alternatively. - F: Weight 1m linear smooth mesh, in grams, 0.26 Ø thread, AISI 304, unstretched resting mesh.

If the diameter of the wire is different, the weight of the mesh is proportional to the section (*) of the wire. For different qualities make conversion according to specific weight of each material.

(*) Section, in the direction of the area (pr2 ).

more common materials

- glossy steel

- galvanized steel

- stainless steel AISI-304 and AISI-316

- Aluminum

- Polypropylene

- Monel

- refractory 25/20

most common applications

- Shock absorbers and anti-vibration shields

- Air filters

- silencers

- antiparasitics

- Fixing of heat insulation

- humidifiers

- heat exchangers

Mesh finish

- Smooth or wavy in “diagonal”, “single spike” or “multiple spike”.

- Smooth or wavy in “diagonal”, “single spike” or “multiple pin”. · All mesh can be supplied wavy.

NOTE: The meshes lose length when they wave them. The maximum ripple with our pinions reduces the length of the mesh by 59%.