Demisters - Technical Design Data

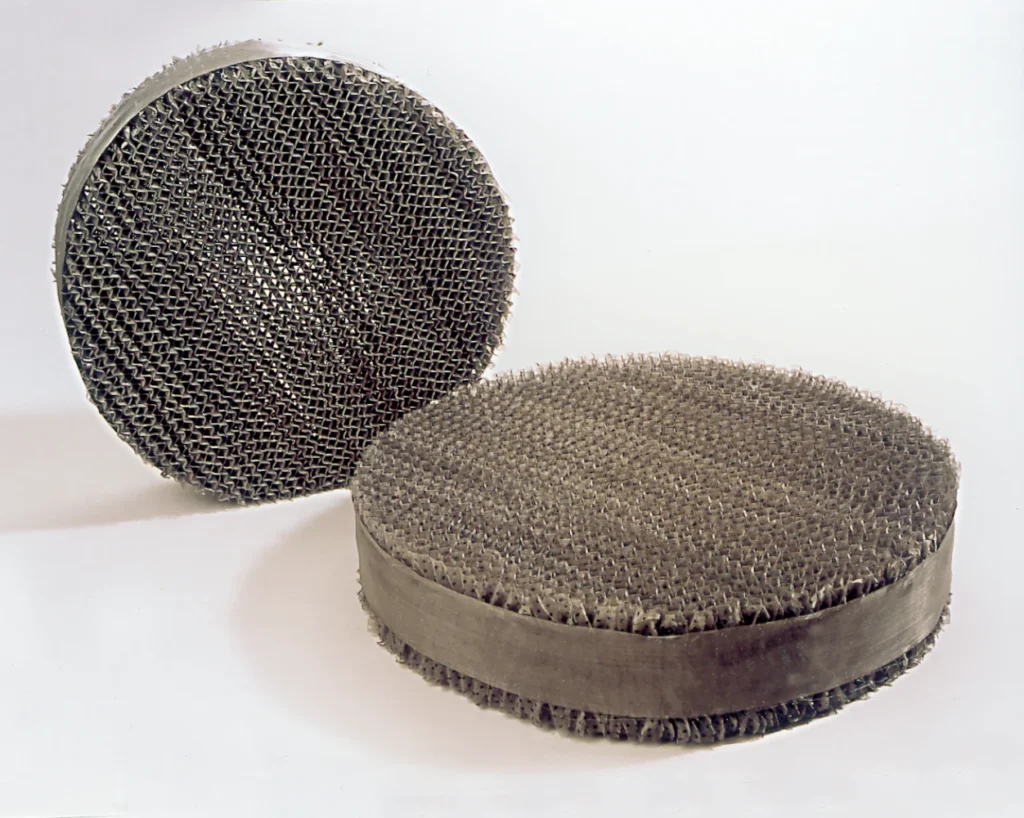

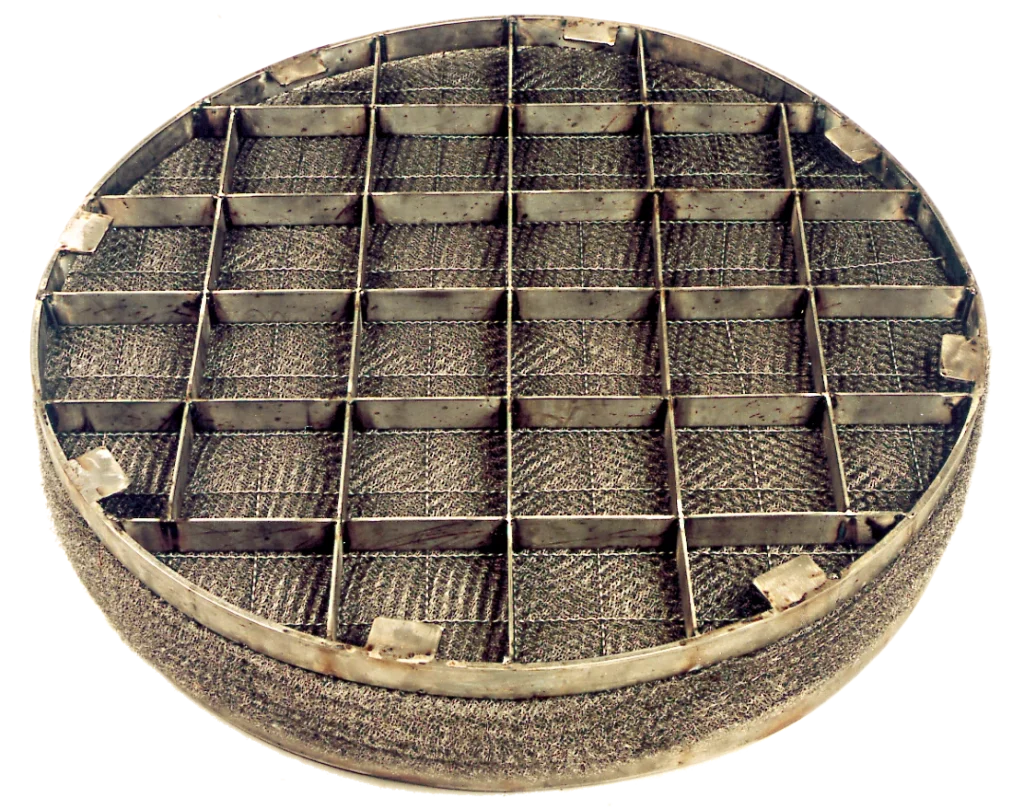

Demisters serve to separate the finest drops carried by a gas or vapor in the most efficient way, whether in a boiling phase, vacuum evaporation or belling of a liquid.

In fact, two phenomena intervene, one mechanical and the other physical, but in no case a leak since the size of Retained drops are not related to the infinitely larger size of the pore or open space. The loss of load or resistance to the passage of the gas is practically imperceptible, however the defogging can achieve an efficiency of 99%.

The demister reaches maximum performance when the speed of the gas or steam oscillates between certain limits:

Vm = K √((d-d)/d)vm = k √((d-d)/d)

- VM: maximum speed.

- K: Viscosity-dependent coefficient, dimension of the

drops, type of fabric, etc., which, due to experience and results

obtained, we have set an average of 0.109. - D: Liquid density (kg/m3 ) under service conditions.

- D: Gas density (kg/m3 ) under service conditions

Once the maximum speed has been obtained, the optimum and minimum speeds of the denebulizer can be set, giving 75% and 30% of the VM respectively to obtain the aforementioned optimal and minimum speeds.

The performance of a denerboler is more affected by low speeds than by highs, therefore, in case of need, It is always advisable to use high speeds.

selected

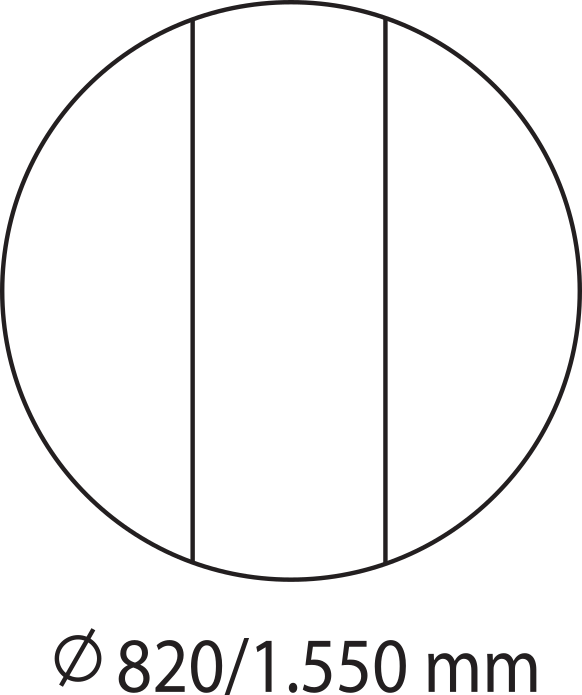

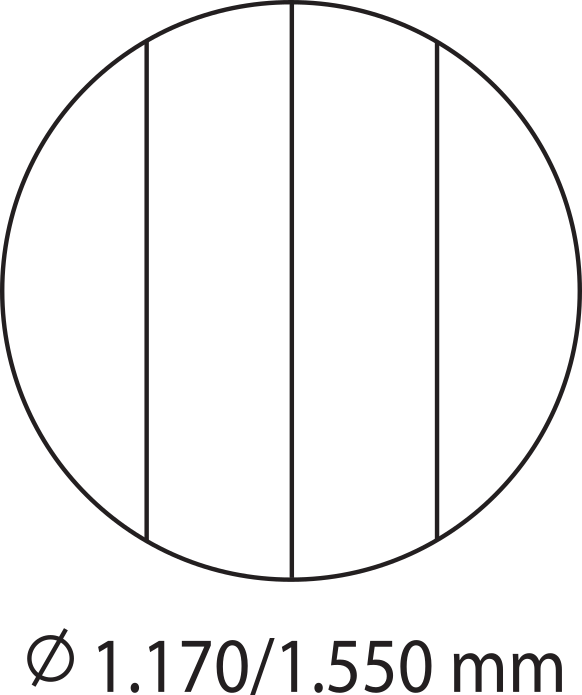

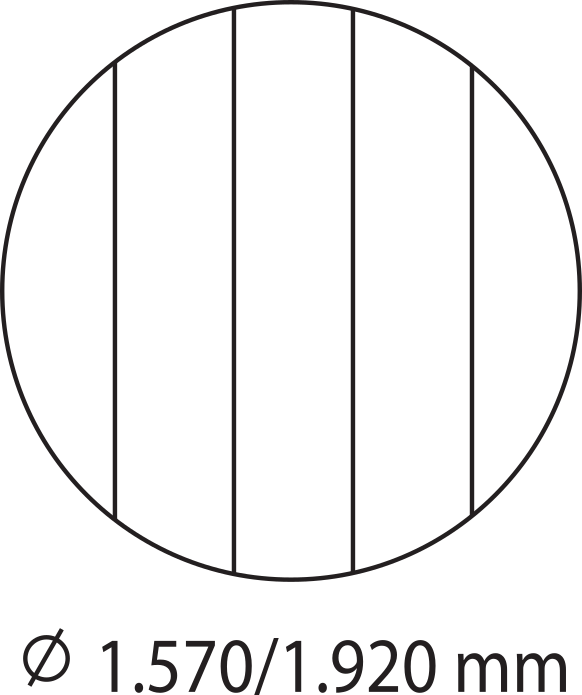

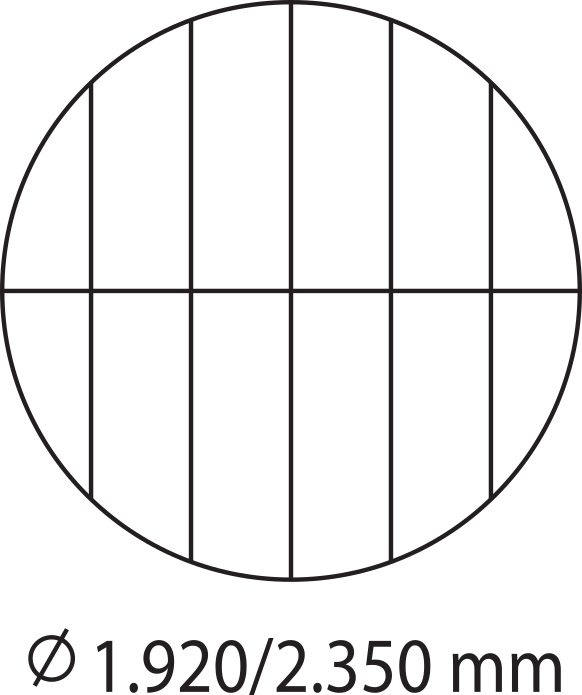

Main types of demisters

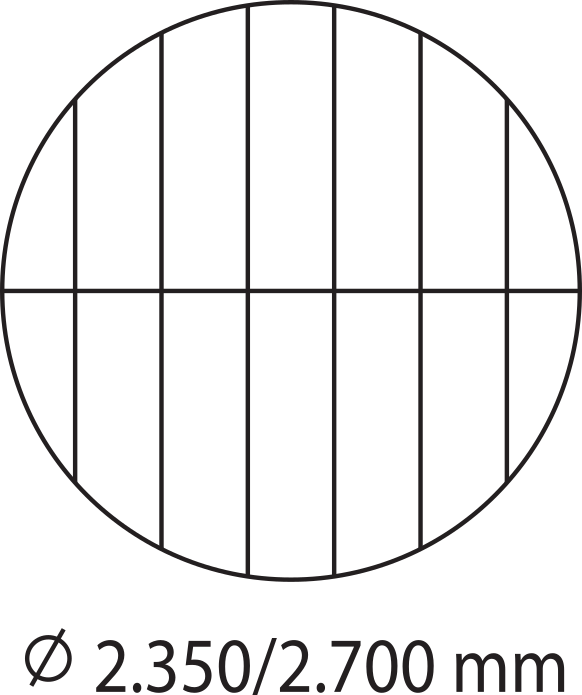

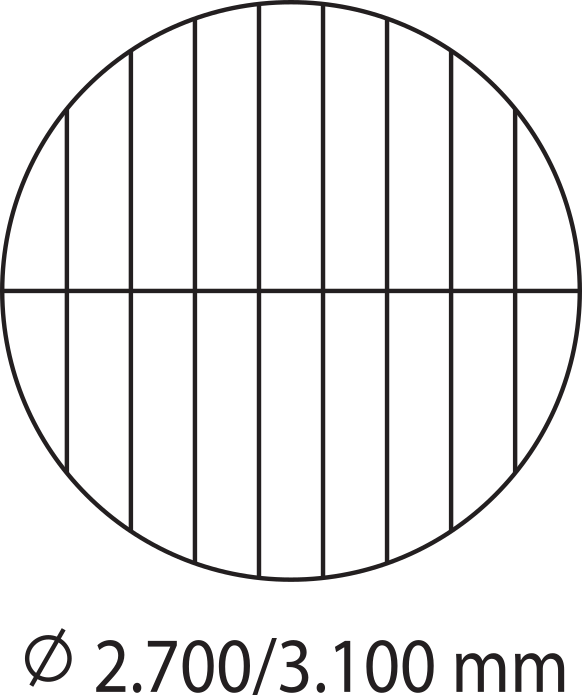

Demisters are classified in different types according to their application, density and contact capacity. This technical table presents the most common configurations used in industrial processes to guarantee an efficient separation of liquids and gases.

| Type | Application | Density (kg/m³) | Contact surface (m²/m³) | Free Volume (%) |

|---|---|---|---|---|

| CD-14 | High gas speeds | 80 | 145 | 99 |

| CD-18 | Viscous liquids, large particles | 100 | 180 | 98.75 |

| CD-30 | Standard, for all uses | 150 | 300 | 98.00 |

| CD-39 | great efficiency. Normally rolled type | 200 | 390 | 97.50 |

| CD-63 | high performance. Slow speeds | 300 | 635 | 96.25 |

| CD-175 | Distillation | 450 | 1750 | 94.00 |

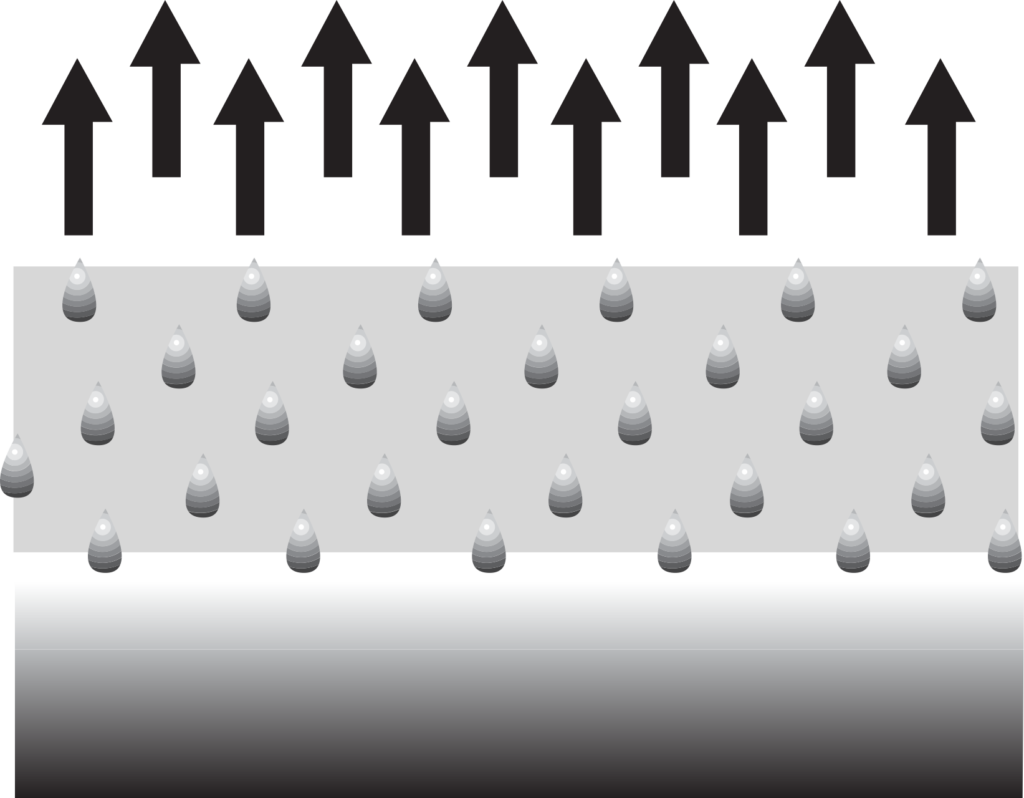

When the fine drops of a liquid are dragged upward by a gas at a certain speed by the labyrinth of a porous structure, sudden changes in the direction of the cloud are produced, these drops against the mesh, giving rise to a phenomenon of coalescence that It forces you to regroup in other larger ones and, by gravity, return to the bottom of the vessel or separation tower.

Advantages of the Demisters

The use of knitted wire mesh in the manufacturing of demisters offers a number of advantages:

Compact and efficient design

Small dimensions thanks to the large contact surface of the mesh.

Gas performance improvement

Increases flow speed, optimizing system productivity.

Reduction of losses in liquid phase

Minimizes energy losses and disturbances in later phases of the process.

Increased purity of gas or steam

Obtaining clean flow, free of liquid contaminants.

Null maintenance and energy saving

Static operation without motors, no maintenance required.

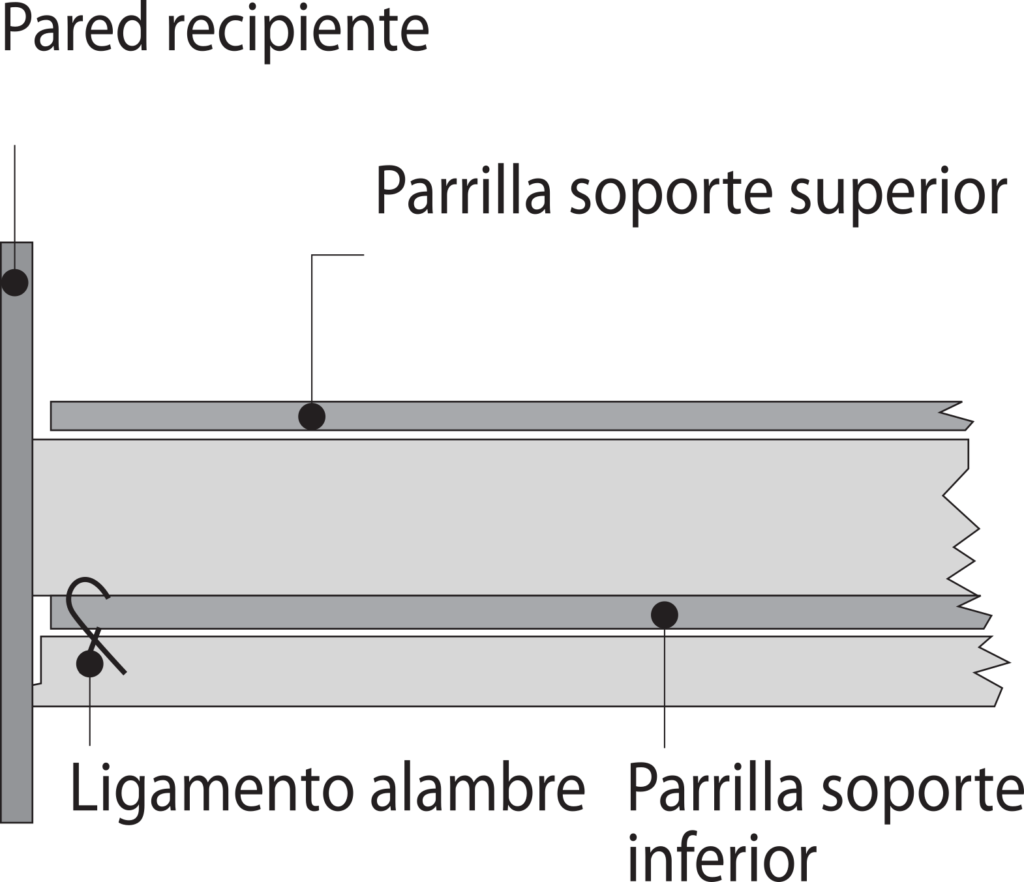

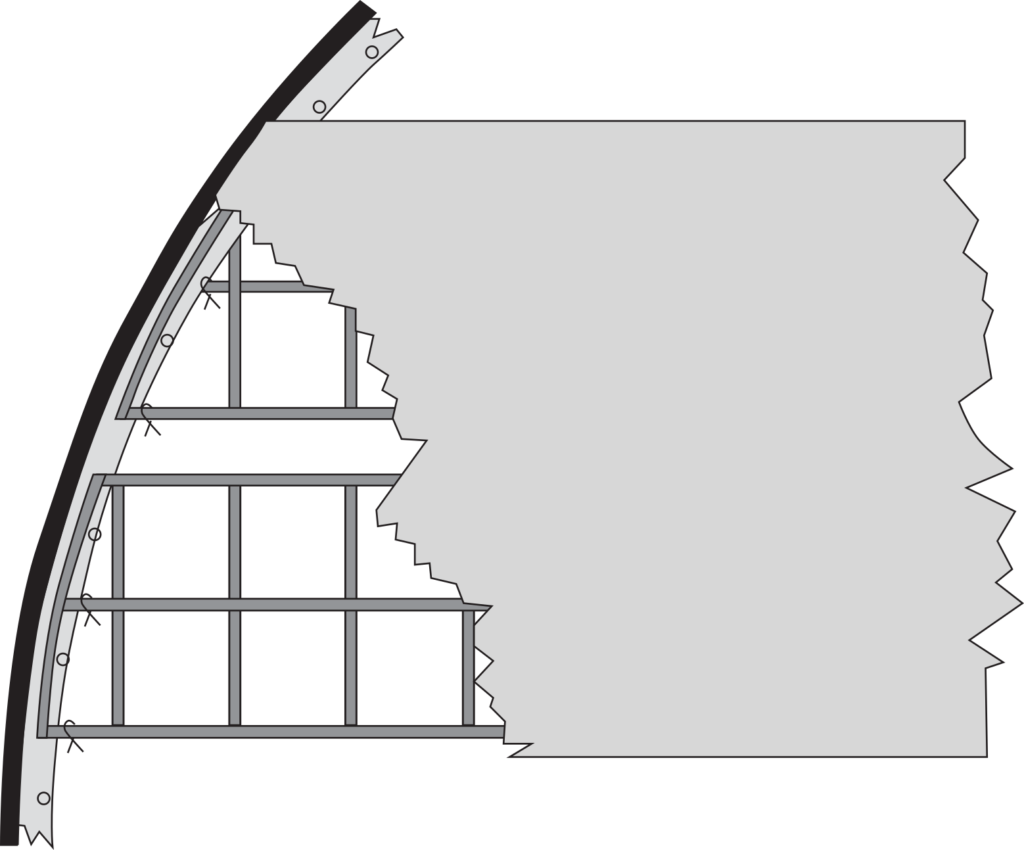

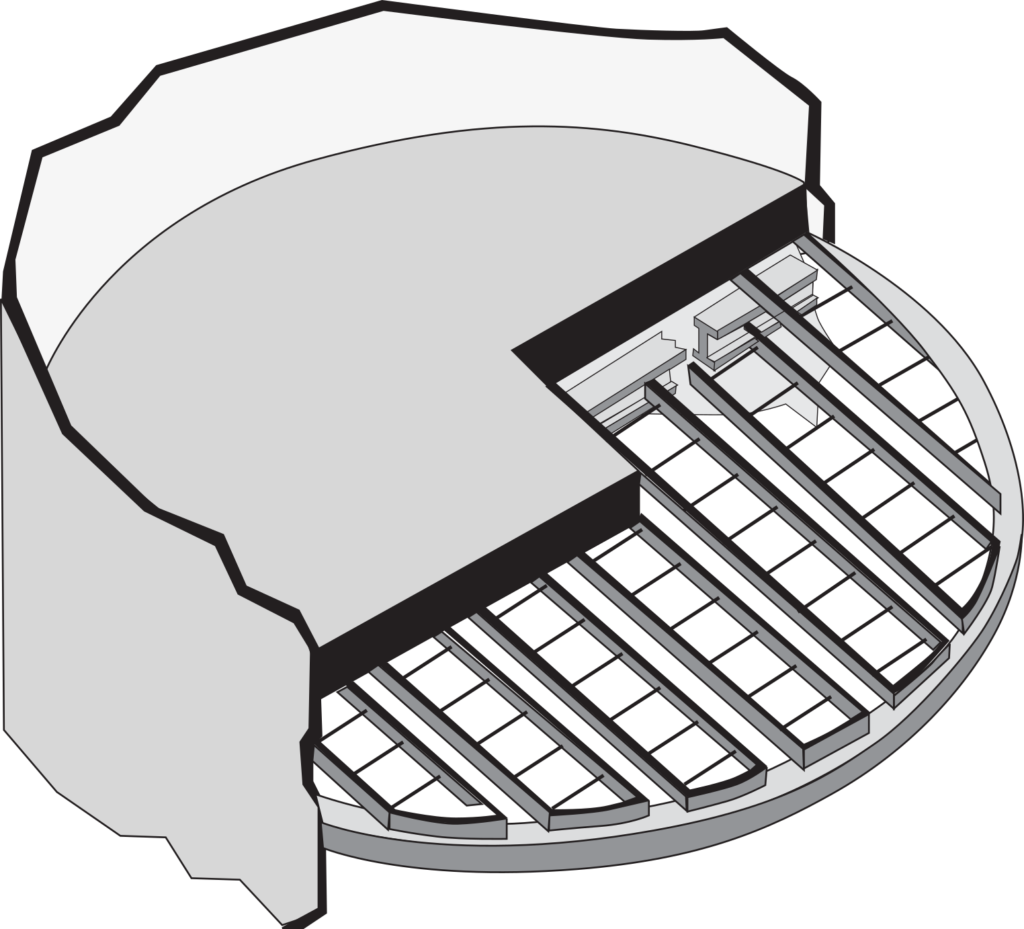

Easy manufacturing and installation versatility

Custom shapes and easy assembly, without special technical requirements.