Characteristics of metal fabrics for industry

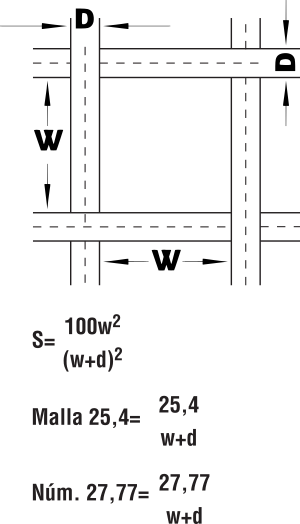

D: Wire diameter in mm.

W: opening (light of the mesh). distance in mm. between two adjoining wires.

In addition to the material of the wire used and the type of fabric, other characteristics indicated in the table are:

S%: useful surface. Approximate percentage of the total area of the openings of a fabric.

kg/m2: Approximate weight in kg. of one m2. of iron/steel wire (see table of conversion factors for other materials).

NUMBER: fabric number. It is the number of mesh steps in a given unit of length. Metallic fabrics are normally defined by the parameters W and D, so this information is merely indicative and only to achieve a simplified description of the fabric, but it is included, being still widely used in two different versions, calculated as follows (values in mm.):

metal fabrics

The different types of fabric used in the manufacture of metal fabrics determine their functionality and technical behavior in industrial applications. Among the most common are:

Smooth fabric

Simple and uniform interlacing, ideal for standard applications.

Twilled fabric

Greater stability and load capacity thanks to its diagonal pattern.

Smooth reps

It allows precise filtration with high thread density in one direction.

REPS ASARGADO

It offers superior resistance and great filtering capacity in extreme conditions.

Each configuration is selected according to the needs of mechanical resistance, filtering precision and structural stability.

Densities and conversion factors

To obtain the approximate weight in kg/m² Of the indicated materials, multiply the weight of the general table by the coefficient Fc.

(Keep in mind that the weight indicated in the table is for stainless steel)

| Material | density (g/cm³) | Conversion Factor (FC) |

|---|---|---|

| Iron / Steel | 7,850 | 1.000 |

| stainless steels | 7,930 | 1.010 |

| Aluminum | 2,700 | 0.343 |

| Copper | 8,900 | 1.134 |

| Brass (Cu Zn37) | 8,450 | 1.076 |

| Brass (Cu Zn20) | 8,650 | 1.102 |

| Phosphor bronze (Cu SN6) | 8,800 | 1.121 |

| Monel 400 alloy | 8,810 | 1.122 |

ISO 9044 standard (Published by International Organization for Standardization) is applicable in everything related to technical requirements, tolerances and conditions of industrial metal fabrics.

| Mesh 25.4 | Filtration in microns (μ) | D (mm) | Weight (kg/m²) |

|---|---|---|---|

| 12×64 l/p | 350 | 0.58 – 0.43 | 4.01 |

| 12×64 l/p | 280 – 300 | 0.61 – 0.41 | 3.90 |

| 24×110 l/p | 112 – 125 | 0.36 – 0.26 | 2.70 |

| 30×150 l/p | 98 – 105 | 0.23 – 0.18 | 1.65 |

| 40×200 l/p | 75 – 80 | 0.18 – 0.14 | 1.35 |

| 50×250 l/p | 60 – 65 | 0.14 – 0.12 | 1.20 |

| 60×570 A/T | 50 – 55 | 0.17 – 0.10 | 1.85 |

| 80×700 A/T | 35 – 40 | 0.10 – 0.08 | 1.32 |

L/P: Smooth fabric A/T: Twilled fabric