What are knitted meshes and deners? And what are they for?

- Separation of mists and vapors in the petrochemical industry.

- Filtration in ventilation and air conditioning systems.

- Optimization in industrial processes such as distillation and condensation.

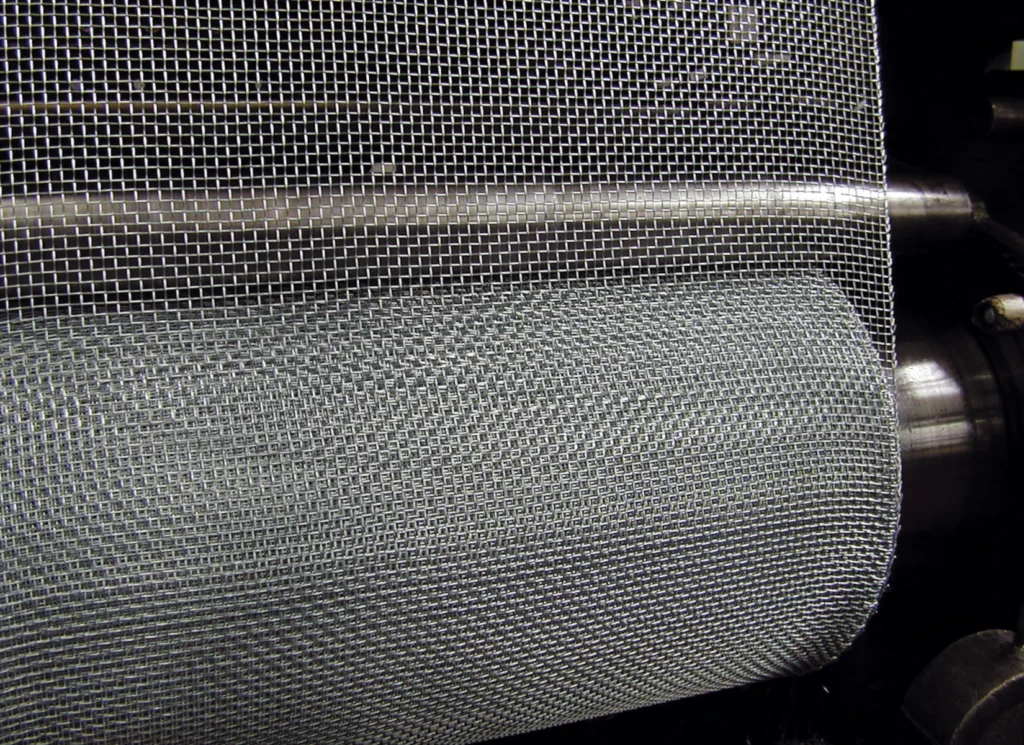

Knitted mesh:

The knitted meshes They are made up of metallic or synthetic threads intertwined in a three-dimensional pattern. Their flexibility and strength make them ideal for various filtration and separation applications.

Desnebulizers (demisters):

They are systems designed with knitted meshes that Capture and remove microscopic droplets in gas flows, improving the efficiency of the process and the purity of the final product.

Industrial applications

Petrochemical and chemical industry

In refineries, chemical and petrochemical plants, the production processes generate vapors and mists loaded with unwanted liquid particles.

Read more...

- Distillation and absorption towers: They remove fine droplets from the gas flow, improving the purity of the product.

- Refining and chemical synthesis processes: They capture liquid contaminants in exhaust gases.

- Plastics and polymer production plants: They prevent contamination in extrusion and reaction stages.

Ventilation and air conditioning systems

HVAC and air treatment systems in Hospitals, laboratories, industrial plants and clean rooms They require advanced filtration to ensure a clean and safe environment.

Read more...

- Air filtration in controlled environments: Prevent the dispersion of particles and liquid contaminants in closed circuits.

- Air conditioning and refrigeration condensers: They improve thermal efficiency by avoiding the accumulation of moisture in ducts and compressors.

- Industrial fumes and gas extraction systems: They retain drops of hazardous chemicals in ventilation processes.

BENEFITS: They prolong the life of the equipment, reduce maintenance and improve air quality.

Industrial Processes and Manufacturing

The knitted meshes They are integrated into machinery and filtration equipment to optimize different industrial processes…

Read more...

- Distillation and fractionation towers: They improve the separation efficiency in the production of fuels and solvents.

- Capacitors and Evaporators: They eliminate unwanted droplets in condensation and heat transfer processes.

- Pharmaceutical and food industry: They guarantee the purity of the product in extraction, filtration and fermentation processes.

- Gas desulfurization processes in thermal power plants: They filter polluting particles in the generation of energy.

Advantages of knitted mesh and demisters

High separation efficiency

They capture microscopic particles and drops.

Chemical and mechanical resistance

Ideal for aggressive environments.

Versatility

Adaptable to different materials, densities and configurations.

Durability and easy maintenance

Designed for consistent long-term performance, reusable and easy to clean, reducing costs.

- materials and manufacturing

Manufacture of knitted meshes

The manufacturing process consists of braiding metallic threads (such as stainless steel, copper or nickel) or synthetics (such as polypropylene or PTFE) in patterns adjusted to the needs of the customer. These meshes can be integrated into standard or custom configurations to be part of filtration systems such as deners.

materials used

| type of material | Examples | properties |

|---|---|---|

| Stainless steel | 304, 316, etc. | High corrosion resistance, durability and thermal stability. |

| Nickel and its alloys | Monel, Inconel, Hastelloy | Excellent chemical and thermal resistance in extreme environments. |

| copper and bronze | Phosphor bronze, brass | Good thermal conductivity and corrosion resistance. |

| synthetic materials | Polypropylene, PTFE (Teflon) | Lightness, chemical resistance and flexibility in aggressive environments. |

The meshes can be customized in shape, density and dimensions according to the needs of each project, allowing them to be adapted to various industrial applications.

Protect your process with advanced filtration systems

- higher efficiency in the elimination of fog and particles in gas and liquid flows.

- High quality materials, such as stainless steel, nickel and technical polymers.

- Adaptability to any industry, including petrochemicals, air conditioning, manufacturing and more.